Yuan, J.; Anantharamkrishnan, V.; Hoye, T. R.; Reineccius, G. A. J. Agric. Food Chem. 2023, 71, 9481–9489.

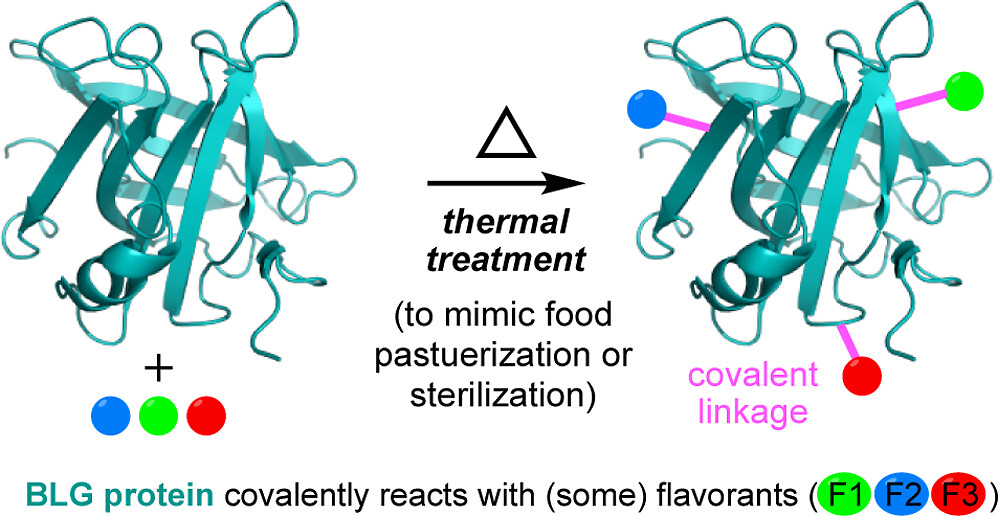

Thermal processing (e.g., pasteurization and sterilization) is a critical step ensuring the microbial safety of our foods. Previous work from our laboratory has examined the covalent reactions occurring between proteins and a broad selection of flavor compounds under ambient storage temperatures (25–45 °C). However, similar research on reactions of flavor compounds with a protein under thermal processing conditions has not been investigated. In the current study, covalent adduct formation between β-lactoglobulin (BLG) and 46 flavor compounds encompassing 13 different classes of functional groups was investigated under pasteurization and sterilization conditions by UPLC–ESI–QTOF–MS. BLG was chosen as a representative protein for this study because it is structurally well characterized, its molecular weight is well suited for ESI–MS analysis (18.2 kDa), and it is broadly used in the food industry. Schiff base, aza-Michael addition, and disulfide linkages were the main types of covalent interactions occurring across the reactive samples. Among them, isothiocyanates, aldehydes, and thiol-containing compounds were generally very reactive. Increasing the severity of the thermal treatment [high-temperature-short-time (HTST) pasteurization, in-container pasteurization (IC), and ultra-high-temperature (UHT) sterilization conditions] accelerated the reactions of BLG with flavor compounds, which revealed reactivity of three flavor compounds not previously observed to react at room temperature (eugenol, 4-vinyl phenol, and 3-nonen-2-one). Ketones [other than 2-hydroxy-3-methyl-2-cyclopenten-1-one (cyclotene), diketones, and unsaturated ketones], alcohols, acids, alkenes (terpenes), esters, lactones, 3-acetylpyridine, methyl anthranilate, vanillin, 2-methylthiophene, and dimethyl sulfone did not show measurable reactivity with BLG under the thermal processing conditions examined. An overall view of the data shows that the HTST heat treatment (72 °C for 15 s) had the least effect on the extent of reaction while in-container pasteurization conditions (63 °C for 30 min) produced a similar extent of reaction as the UHT (130 °C 30 s) heat treatment. These varying extents of adductation are in reasonable accord with what one might expect, given that the rates of most classes of chemical reactions occurring near ambient temperature increase by a factor of 2–4 for each increase of 10 K in temperature. Unfortunately, our methodology did not permit us to obtain meaningful data using the most aggressive standard sterilization thermal conditions (110 °C for 30 min) because extensive aggregation/coagulation removed essentially all of the BLG protein from the reaction mixtures prior to MS analysis.